Expert Guide to Packaging Machine Repair for Optimum Efficiency

Expert Guide to Packaging Machine Repair for Optimum Efficiency

Blog Article

Ensuring Smooth Operations and Cost-Efficiency: The Essential Advantages of Purchasing a High-Performance Packaging Maker

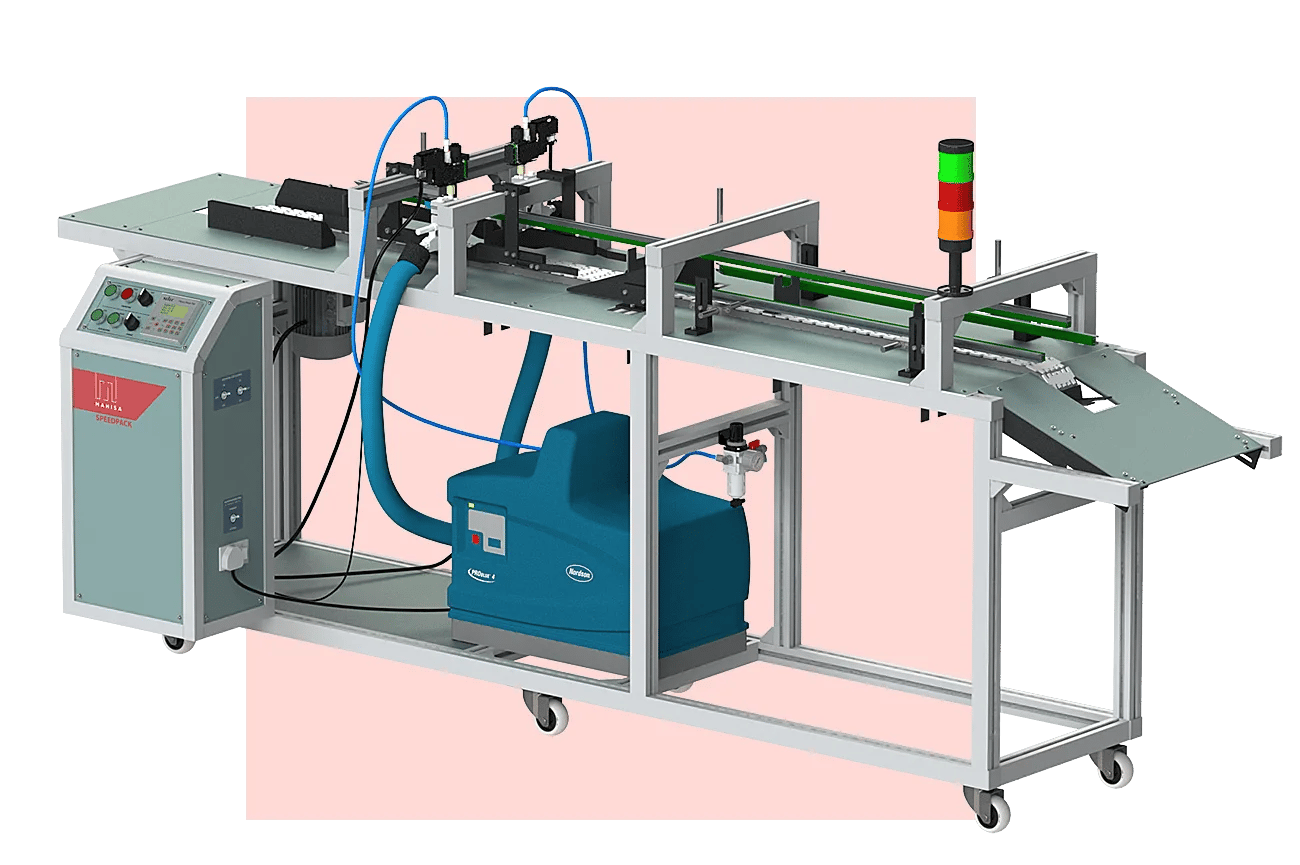

Buying a high-performance packaging equipment can considerably influence the functional efficiency and cost-effectiveness of a manufacturing facility. This critical decision surpasses simple automation; it serves as a foundation for streamlining procedures, enhancing source application, and guaranteeing smooth manufacturing flow. The benefits of such an investment surge throughout various facets of a business, from increased productivity and decreased downtime to enhanced high quality control and sustainable packaging services. As sectors navigate an increasingly competitive landscape, the important of leveraging advanced modern technologies like high-performance product packaging machines ends up being not just a selection however a requirement.

Improved Efficiency and Outcome

Buying a high-performance packaging equipment can substantially improve efficiency and outcome in a manufacturing center. These machines are engineered to operate successfully, making sure smooth packaging procedures that save time and resources. By automating jobs such as loading, sealing, labeling, and palletizing, high-performance product packaging equipments enhance operations, minimizing the need for manual work and reducing the threat of mistakes.

In addition, these devices are developed to operate at ideal rates while keeping precision and uniformity in product packaging, resulting in higher outcome degrees. With innovative innovation and functions like automatic adjustments, quality assurance systems, and real-time monitoring, high-performance packaging equipments can deal with a vast array of product packaging needs easily. This versatility permits manufacturers to satisfy differing production demands without endangering on top quality or efficiency.

Reduced Downtime and Delays

To optimize functional efficiency, high-performance packaging machines are engineered to lessen downtime and delays in manufacturing procedures. By integrating sophisticated modern technology and durable layout components, these machines can spot problems proactively, carry out self-diagnosis, and also execute troubleshooting procedures without human intervention. Furthermore, predictive upkeep attributes enable timely maintenance of components prior to they fail, protecting against unforeseen failures that might stop manufacturing.

In addition, high-performance product packaging equipments are furnished with efficient changeover mechanisms that facilitate fast changes between various product kinds or product packaging layouts. This capability decreases the moment needed for setups and adjustments, consequently decreasing downtime related to reconfiguring the equipment for differing production requirements. Automation functions such as automatic reel splicing and continual operation tracking add to undisturbed manufacturing runs and smooth workflow administration.

Boosted Top Quality Control Measures

Enhancing quality control procedures in product packaging procedures is important for guaranteeing item uniformity and meeting consumer assumptions. Applying a high-performance product packaging device can significantly boost quality assurance by reducing errors and flaws in the packaging process. These machines are outfitted with advanced technologies such as sensors, cams, and automated assessment systems that allow real-time monitoring and detection of any type of deviations from top Full Article quality criteria.

By buying a high-performance packaging maker, firms can develop rigid top quality control protocols that assist in determining problems early in the production cycle. This aggressive approach permits for immediate restorative activities to be taken, minimizing the possibility of faulty items reaching the market. Additionally, the precision and accuracy of high-performance packaging machines add to the overall quality guarantee procedure, guaranteeing that each product is packaged correctly and satisfies the needed specifications.

Expense Financial Savings and Efficiency Gains

Enhanced quality assurance actions achieved with the execution of high-performance packaging devices not only boost product consistency however additionally pave the method for considerable cost financial savings and efficiency gains in the packaging process. By making sure that each product is precisely evaluated, secured, and classified, these equipments reduce the probability of mistakes that can lead to costly rework or product recalls. Additionally, high-performance packaging makers run at greater rates and with higher accuracy, boosting overall manufacturing efficiency and output.

Furthermore, these devices are developed to reduce product waste by maximizing the use of product packaging materials such as labels, films, and boxes - packaging machine repair. This waste decrease not only reduces material costs but likewise contributes to ecological sustainability initiatives. Additionally, the automation abilities of high-performance product packaging equipments simplify the product packaging process, decreasing the need for manual work and the associated labor costs. On the whole, buying high-performance packaging machines causes concrete cost financial savings, improved operational performance, and improved competitiveness in the market.

Sustainable Product Packaging Solutions

The assimilation of sustainable methods right into packaging options is coming to be progressively crucial in modern industries. As customers come to be more environmentally mindful, organizations are under stress to reduce their environmental impact. Lasting product packaging remedies offer a means to meet this need while also enjoying numerous benefits.

One secret advantage of sustainable product packaging is its favorable influence on the atmosphere. By lowering and making use of green products waste, firms can aid lower air pollution and save natural sources. In addition, lasting product packaging can boost brand name track record and draw in environmentally mindful consumers.

Furthermore, purchasing sustainable product packaging options can bring about set you back savings in the future. While initial implementation costs may be greater, reduced product use and enhanced operational efficiency can lead to lower expenses over time. Conforming with regulations concerning sustainability click for source can help firms prevent fines and fines.

Final Thought

Finally, spending in a high-performance packaging machine uses many advantages such as enhanced performance, reduced downtime, enhanced quality control, price savings, and sustainable product packaging remedies. These benefits add to smooth procedures and cost-efficiency within a production environment. By integrating advanced innovation and automation, services can maximize their product packaging procedures, increase outcome, and preserve high quality criteria while decreasing functional costs.

With advanced modern technology and functions like automatic modifications, high quality control systems, and real-time monitoring, high-performance packaging equipments can deal with a large range of product packaging needs with simplicity. Executing a high-performance product packaging device can dramatically improve high quality control by decreasing errors and issues in the product reference packaging process. packaging machine repair.Enhanced quality control measures accomplished with the application of high-performance packaging devices not only improve item uniformity yet also pave the way for considerable expense financial savings and efficiency gains in the packaging process. The automation abilities of high-performance packaging makers enhance the product packaging procedure, reducing the need for manual labor and the associated labor expenses.In final thought, spending in a high-performance packaging machine provides countless advantages such as improved performance, decreased downtime, enhanced high quality control, expense savings, and sustainable packaging remedies

Report this page